The Agent Economy: Why Enterprises Are Shifting from LLMs to Autonomous Agents

Major platforms launched agent frameworks in January 2026. CTOs adopting autonomous agents early are gaining an 18-month competitive advantage. Here's why.

Exploring Cutting-Edge Technology in AI, Machine Learning, and Data Analytics

Major platforms launched agent frameworks in January 2026. CTOs adopting autonomous agents early are gaining an 18-month competitive advantage. Here's why.

Learn strategies for identifying and mitigating potential harms when developing and deploying custom large language models.

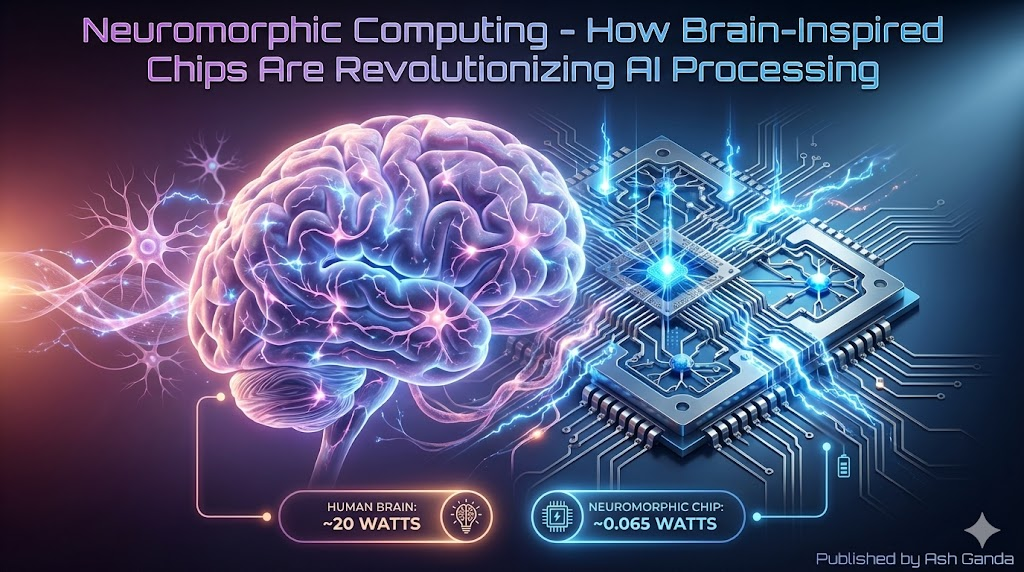

Discover how neuromorphic computing mimics biological neural networks to create energy-efficient AI hardware, featuring spiking neural networks and event-driven processing for next-generation intelligent systems.

Enterprises waste billions annually on wrong build-vs-buy decisions. A strategic framework for technology investment that aligns with business differentiation.

Enterprise AI fails not from model limitations but from prompt design. These production patterns separate demos that impress from systems that deliver consistent business value.

Enterprise systems that ship confidently invest in testing strategically, not comprehensively. These patterns separate teams that deploy fearlessly from those trapped in manual regression.

Join me in discovering the latest developments in artificial intelligence, machine learning, and data analytics.

Let's Connect