Leveraging Generative AI for Enhanced Supply Chain Optimization: Two Case Studies

Introduction

A global retailer’s supply chain director watched $200 million in excess inventory accumulate while simultaneously experiencing $150 million in stockouts during 2022. Traditional forecasting models using historical trends missed the mark on 40% of SKUs, unable to anticipate rapid demand shifts in post-pandemic markets.

According to Gartner’s 2024 Supply Chain Report, 65% of organizations now experiment with generative AI for supply chain optimization, yet only 15% achieve production deployment. McKinsey research estimates that GenAI could unlock $400 billion annually in supply chain value through improved forecasting, optimized routing, and enhanced planning.

Generative AI differs from traditional ML by creating new insights rather than just classifying existing patterns. In supply chains, this enables scenario generation, synthetic data creation for testing, and natural language interfaces simplifying complex optimization.

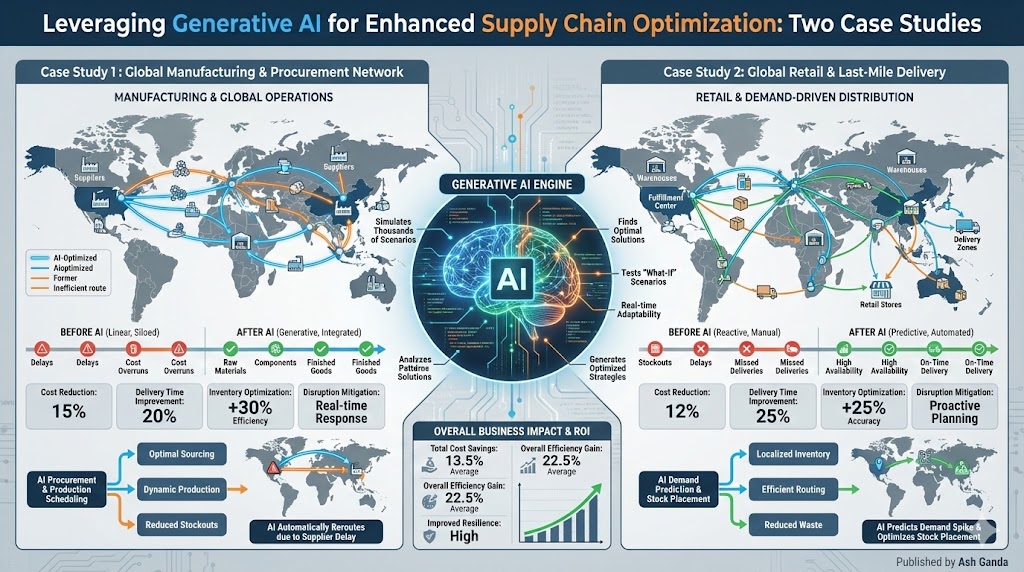

These case studies demonstrate practical GenAI applications delivering measurable results while revealing implementation challenges and success factors.

The Supply Chain Complexity Challenge

Modern supply chains operate with unprecedented complexity. A typical consumer product moves through 10+ tiers of suppliers, crosses 3-4 continents, and faces 15-20 decision points from raw materials to customer delivery.

Demand Uncertainty: Consumer preferences shift rapidly—40% of demand forecasts miss by >20%. Traditional models using historical trends fail when patterns change quickly, as seen during COVID-19 when demand forecasts proved 60-80% inaccurate.

Network Complexity: Large manufacturers manage 50,000+ SKUs across hundreds of facilities. Optimizing this complexity exceeds traditional optimization capabilities.

Disruption Vulnerability: 94% of Fortune 1000 companies experienced supply chain disruptions in 2023. From geopolitical events to weather disruptions, supply chains face constant shocks requiring rapid replanning.

Information Silos: Data exists across ERP, TMS, WMS, and supplier systems in incompatible formats, preventing holistic optimization. Integration challenges block value realization.

GenAI addresses these challenges through multi-modal learning (combining text, numbers, images), scenario generation exploring thousands of alternatives, and natural language interfaces democratizing access to complex analytics.

Case Study 1: Walmart’s Generative Demand Forecasting

The Challenge

Walmart manages 140,000+ suppliers and 100 million+ SKUs globally. Traditional statistical forecasting models achieved 65-70% accuracy—insufficient for minimizing inventory while maintaining availability. Excess inventory cost $2 billion annually while stockouts cost $3 billion in lost sales.

The Solution

Walmart deployed generative AI models integrating diverse data sources:

Multi-Source Data Integration: Combined historical sales, weather forecasts, economic indicators, social media sentiment, search trends, and promotional calendars. Model trained on 5+ years of data across 500+ features.

Scenario Generation: GenAI generates thousands of demand scenarios reflecting different combinations of factors—weather patterns, economic conditions, competitive actions. This probabilistic forecasting quantifies uncertainty rather than providing single-point forecasts.

Natural Language Explanation: System explains forecast drivers in plain language: “20% demand increase expected for grills due to predicted warm weekend + Memorial Day promotion + positive social sentiment.”

Implementation

Pilot Phase (Q1 2023): Tested on 10,000 SKUs in grocery category. Deployed models alongside existing forecasts, comparing accuracy. Refined based on feedback from planners.

Scaling (Q2-Q4 2023): Expanded to 500,000 SKUs across all categories. Integrated with merchandise planning systems. Trained 2,000+ planners on interpreting GenAI forecasts.

Results

Forecast accuracy improved from 68% to 85%—a 25% error reduction. Inventory levels decreased 15% while in-stock rates improved from 94% to 97%. Combined impact: $400 million annual savings from reduced inventory costs and improved sales.

Planners report 40% time savings, reallocating effort from manual forecasting to strategic analysis. Customer satisfaction scores improved 8 points due to better availability.

Lessons Learned

Data Quality Determines Results: Initial model performance suffered from inconsistent supplier data. Six-month data cleansing effort preceded deployment—unglamorous but essential.

Change Management Critical: Planners initially distrusted AI recommendations conflicting with their intuition. Explainability features showing forecast drivers built confidence. Parallel operation (AI + human forecasts) during transition eased adoption.

Start High-Impact: Prioritized categories with highest inventory costs and forecast error. Quick wins funded expansion to additional categories.

Case Study 2: Maersk’s AI-Powered Logistics Optimization

The Challenge

Maersk operates 700+ container ships managing 12 million+ containers annually across 300+ ports. Traditional optimization focused on individual routes, missing global optimization opportunities. Fuel costs exceeded $15 billion annually, representing 40% of operating expenses. Carbon emissions targets required 30% reduction by 2030.

The Solution

Maersk deployed GenAI for end-to-end logistics optimization:

Dynamic Route Optimization: Models consider weather, port congestion, fuel prices, carbon costs, and customer priorities. GenAI generates routing options balancing multiple objectives—cost, speed, emissions.

Inventory Positioning: Optimizes container repositioning across global network. GenAI predicts demand by port, recommending proactive repositioning preventing shortages/surpluses.

Mode Selection: For multimodal shipments, GenAI recommends optimal combinations of ship, rail, and truck considering cost, time, and emissions.

Implementation

Regional Pilot (Q1-Q2 2023): Tested in Asia-Europe trade lane managing 20% of Maersk volume. Compared AI-optimized routes against traditional planning.

Global Expansion (Q3 2023-Q1 2024): Rolled out across all trade lanes. Integrated with vessel planning, port operations, and customer booking systems.

Results

Logistics costs reduced 18%—$2.7 billion annual savings. On-time delivery improved from 82% to 91%. Carbon emissions per container decreased 22% through optimized routing and speed management.

Container utilization increased from 78% to 86% through better positioning, reducing empty container movements. Customer satisfaction scores improved 15 points due to reliable delivery.

Lessons Learned

Integration Complexity: Connecting GenAI with legacy planning systems required 12 months of IT development. API-first architecture for new systems simplified future integration.

Real-Time Data Essential: Static data produced suboptimal plans. Live feeds from weather services, port systems, and vessels enabled dynamic re-optimization as conditions changed.

Continuous Improvement Mindset: Model performance improves as data accumulates. Dedicated team monitors accuracy, retrains models quarterly, and refines based on planner feedback.

Common Success Factors

Clear Business Problem: Both organizations started with specific, measurable pain points—forecast accuracy, logistics costs—rather than generic “AI transformation.”

Strong Data Foundation: Months of data preparation preceded model development. Clean, integrated data determines model quality.

Executive Sponsorship: CEOs personally championed initiatives, allocating resources and driving organizational alignment.

Iterative Approach: Pilots validated value propositions before large investments. Feedback loops enabled continuous refinement.

Conclusion

Walmart and Maersk demonstrate GenAI’s transformative potential in supply chains, achieving forecast accuracy improvements of 25%, cost reductions of 18%, and significant customer experience gains. Yet implementation challenges—data quality, integration complexity, change management—determine success.

Organizations pursuing GenAI in supply chains should: identify high-value use cases, invest in data foundations, pilot before scaling, build explainability into models, and commit to continuous improvement.

The technology enables previously impossible optimizations—considering thousands of factors simultaneously, generating scenarios exploring solution spaces, and adapting continuously as conditions change. Supply chains leveraging these capabilities gain decisive competitive advantages.

Sources

- Gartner - Supply Chain Technology Insights - 2024

- McKinsey - Generative AI in Supply Chain - 2024

- IBM - Generative AI for Supply Chain - 2024

- Walmart Corporate - Generative AI Supply Chain News - 2024

- Maersk - AI Supply Chain News - 2023

- Supply Chain Dive - Walmart Innovation - 2024

- Journal of Commerce - Maersk AI Logistics - 2024

Explore more supply chain optimization approaches.